Robotization of packaging and mixing

We provide comprehensive packaging and mixing robotization solutions that deliver fast cycle times and high process precision. Our systems are tailored to pack a wide variety of products – from small packages to larger unit packs, as well as to mix products with different ingredients. We design each station individually according to the customer’s requirements, ensuring full flexibility and process optimization. For large capacities, we offer robots for packaging in various layouts, mixing systems, as well as automatic buffer tables and product storage systems.

Robotization of packaging and mixing strengthens your company's competitiveness

- High packaging and mixing efficiency

- Precise and even blending of ingredients

- Automatic adaptation to different packaging formats

- Reduced operating costs by eliminating manual processes

- Ability to reassign employees to more demanding tasks

- No downtime associated with human interruptions

- Excellent quality control thanks to monitoring systems

- Flexibility to handle a variety of products and packaging

- High reliability and longevity of robotic systems

- Simple integration into existing production lines

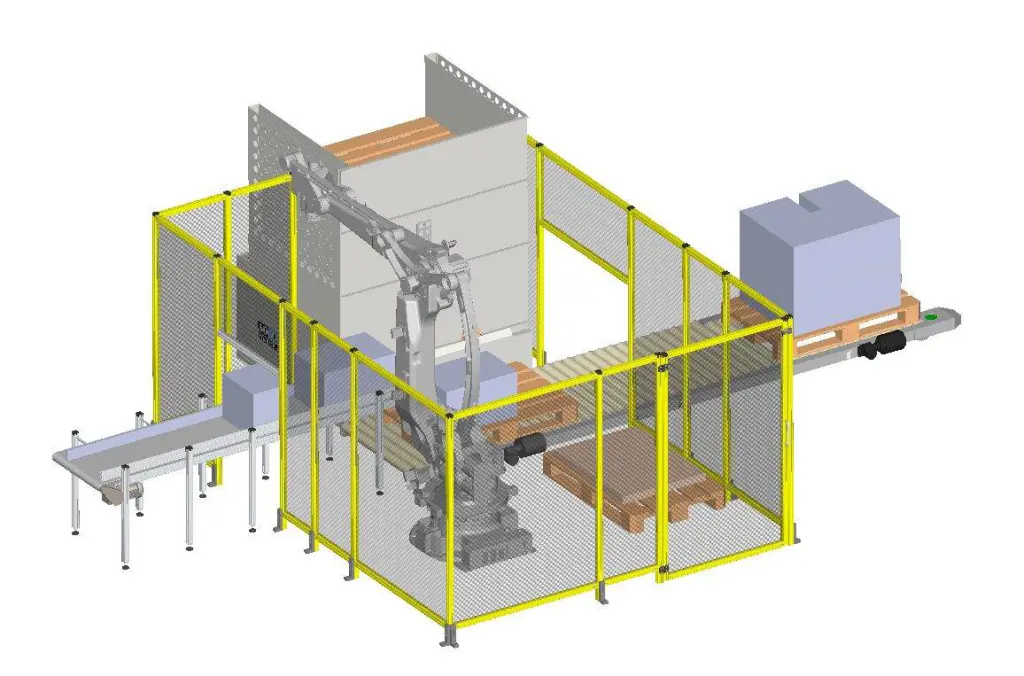

Robotization of packaging - eliminate bottlenecks and increase production efficiency

Manual packaging and product mixing can become a bottleneck in production processes, leading to delays and suboptimal productivity. In response to these challenges, more and more companies are choosing to automate these key production steps. With modern robotic solutions, the packaging and mixing process can be precisely tailored to different types of products, regardless of shape, weight or packaging material.

Advantages of robotic packaging and mixing:

Increased efficiency and quality: Industrial robots and cobots provide uninterrupted and accurate work, regardless of the type of product, which increases the quality and speed of production.

Safety and comfort: Automation that eliminates the need to manually pack and mix heavy or fragile products reduces the risk of injury and fatigue, providing better working conditions.

Lower operating costs: Robotization of the process reduces costs associated with hiring workers for manual tasks and minimizes downtime associated with human error.

Flexibility: automated packaging and mixing systems can handle different types of products and adapt to changing production requirements, making them ideal for dynamic industrial environments.

Investing in state-of-the-art robotic packaging and mixing systems is the key to increasing efficiency, reducing costs and improving quality, giving you a competitive advantage in the market.

Our robotic packaging and mixing solutions:

Packaging Machines Case Packer

Case Packer packaging machines are devices that automate the process of packing products into cartons, ensuring fast, precise and efficient stacking of goods at the final stage of production.

Automatic product mixing

Automated product mixing is a process in which machines combine a variety of products, such as packaging or unit goods, into appropriate sets and loads, which are then packed into cartons.

Get a free audit of production processes in your company!

Find out how much you can gain with our solutions!