LaserClean is an innovative alternative to traditional cleaning methods such as sandblasting and dry ice cleaning. It offers unparalleled precision, speed and reliability, making it an excellent investment for any company.

Laser cleaning is a guarantee of effective and environmentally friendly cleaning, which is perfect for any industry, eliminating the compromises between traditional methods and modern laser technology.

What can be cleaned with a laser?

How do laser scrubbers work?

LaserClean is an innovative alternative to traditional cleaning methods such as sandblasting and dry ice cleaning. It offers unparalleled precision, speed and reliability, making it an excellent investment for any company.

Laser cleaning is a guarantee of effective and environmentally friendly cleaning, which is perfect for any industry, eliminating the compromises between traditional methods and modern laser technology.

Laser cleaning

Explore models

LaserClean Puls Mini

Power up to 300W Optical fiber 5m Pulse up to 5mJ

starting at PLN 58,700.00 net

LaserClean Puls

Power up to 1000W Optical fiber 10m Pulse up to 15mJ

starting at PLN 81,200.00 net

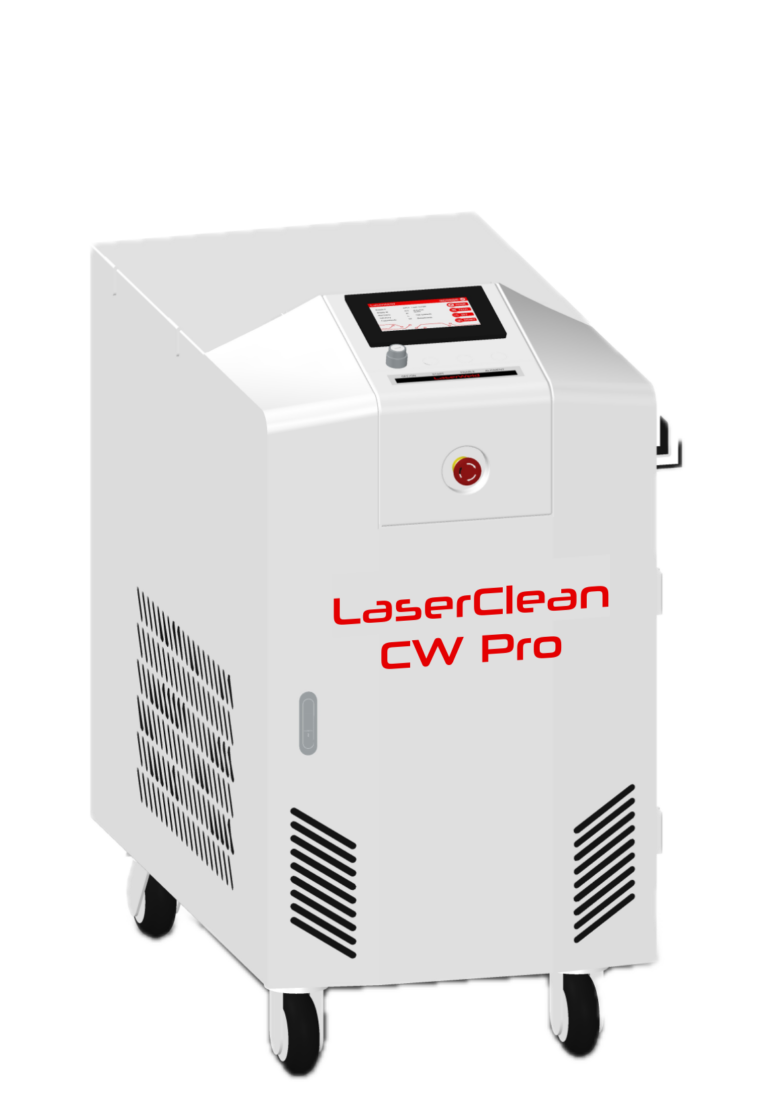

LaserClean CW Pro

Power up to 3000W 15m light cable Continuous operation

starting at PLN 48,300.00 net

Pulsed laser scrubbers - advantages

High Efficiency

High efficiency of laser blasters, reaching up to 50 m²/h, for comparison, sandblasting settles down to 10 m²/h – this is 5 times more.

Such efficiency makes laser cleaning an ideal solution for large surfaces that require quick and thorough removal of contaminants such as rust, paint or industrial deposits.

Quick return on investment

The rapid return on investment of laser scrubbers is one of the key benefits for choosing this modern technology.

Laser scrubbers, thanks to their high efficiency and precision, significantly speed up cleaning processes compared to traditional methods such as sandblasting or dry ice cleaning.

No secondary waste

The absence of secondary waste is one of the key advantages of laser cleaning, which significantly distinguishes this technology from traditional methods such as sandblasting or chemical cleaning.

The laser cleaning process is completely non-contact and requires no abrasives, chemicals or additional cleaning media.

Free demonstration

pulsed laser cleaner!

Fill out the form and our expert will help you choose the optimal laser solution for your needs.

Cleaning test on your material

A full day of technical presentation

Free process analysis

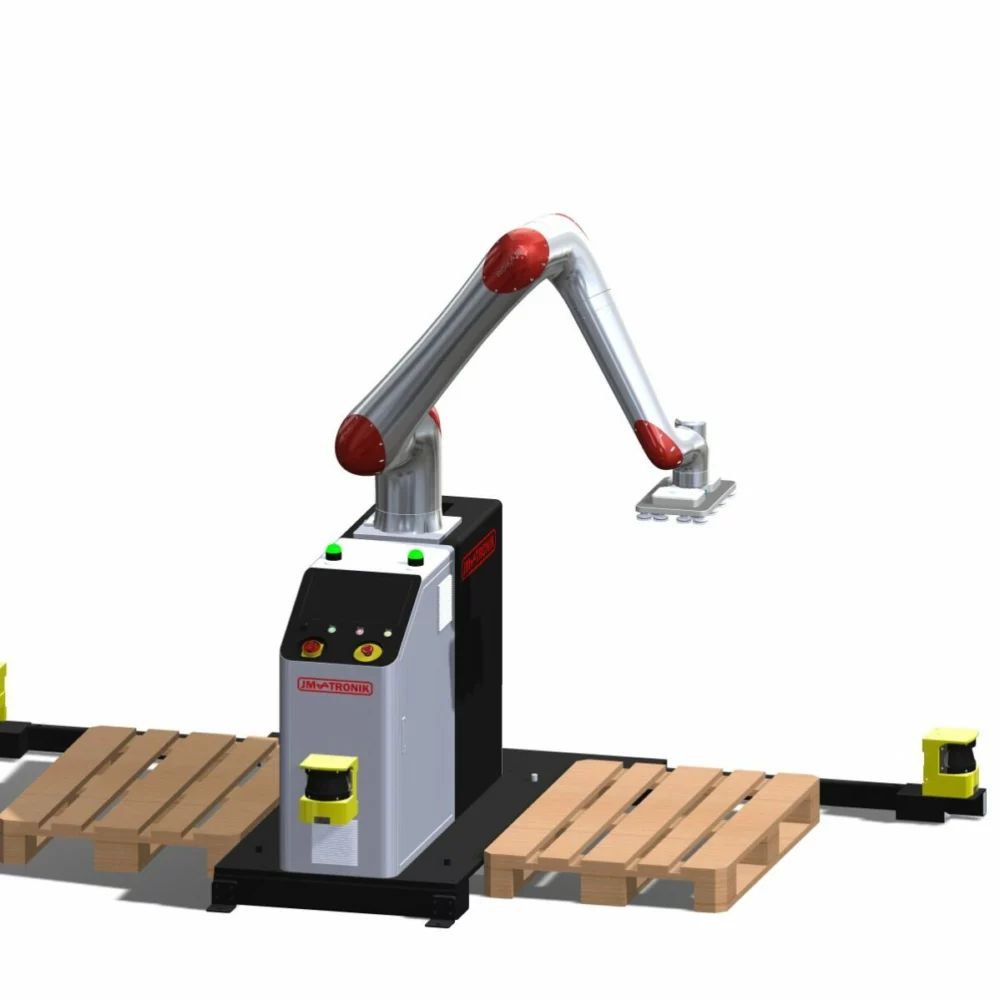

Why choose jm-tronik?

JM-TRONIK is a Polish company that has been in existence since 1981. Our experience is mainly years of work in energy and laser technologies.

▸ Honorable mention of STOM 2024 trade fair

▸ Innovative control

▸ S ervice parts warehouse

▸ Certified personal protective equipment EN 207

▸ Vocational training

Support

At jm-tronik, we are more than just a manufacturer of pulsed laser scrubbers – we are your dedicated partner on your laser cleaning journey. Our commitment to your success includes a suite of comprehensive support services tailored to your needs:

▸ Installation of the machine

▸ 1-day health and safety training

▸ O nline support

▸ O n-site service assistance – up to 48h

▸ S election of cleaning parameters and technology

Akcesoria i części

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

LaserClean Puls Mini – pulsacyjna oczyszczarka laserowa

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page