ROKAE xMate Cobots

collaborative robots for tasks

werms of precision and reliability

ROKAE’s xMate CR Series Cobots combine safety, flexibility and intuitive programming with rapid integration into production environments. With a 9-year maintenance-free service life and robust design, they are a reliable support for modern manufacturing plants that expect high performance and reliability.

A global labor shortage is increasing demand for cobots and collaborative robots in industrial manufacturing. These intelligent machines today need to be safer, more flexible and easier to use than ever before.

Collaborative robots are opening up new opportunities for man and machine to work together.

The new generation of ROKAE cobots is equipped with intelligent force sensors and advanced vision systems to move from traditional open-loop learning to an intelligent closed-loop process. This allows ROKAE cobots to react dynamically to their environment and interact safely with humans.

This innovative solution opens the door to many new applications, making cobots an invaluable support and partner in production.

Why choose

Collaborative robots

Security

● Sensitivity improved tenfold with collision detection using torque sensors.

● More than 21 TÜV safety functions, meets functional safety standards: ISO 13849-1, ISO 10218-1/PL d, category 3; ISO 15066.

● Redundant monitoring of sensor information in a dual channel and independently certified safety controller.

● Position holding accuracy better than ±0.1 mm with power on and off, powered by suction brake and dynamic feedforward compensation.

Performance

● State-of-the-art motion control technologies for industrial robots: OptiMotion, TrueMotion and SyncMotion.

● Excellent robot path accuracy supported by dynamic feedforward compensation and dynamic modeling based on more than 2,000 parameters.

● Increased lifting capacity by 20% thanks to a customized motor drive control system.

Multitasking

● Powerful yet flexible robot control based on a hybrid force and position control system.

● Performance of force control tasks improved by more than three times with highly dynamic force control.

● Precision grinding and assembly without the need for expansion, thanks to built-in sensors at the joints and a complete set of force control processes.

Ease of use

● Direct learning control with 1N based on point position and continuous trajectory.

● Graphical programming interface with block diagrams allows users to get started within an hour.

● Friendly development environment and support for an open ecosystem with more than 100 extension tools in 5 categories.

● Proprietary offline programming software Rokae Studio, which supports simulations for all models.

● The possibility of using a design without a control cabinet, which reduces the weight of the system by 50% and enables quick installation and flexible deployment.

Reliability

● Motion planning based on dynamic constraints ensures high performance, overload protection and extended life.

● More than 100 verification experiments, 20+ factory tests and MTBF > 80,000 h.

● IP67 protection level meets the requirements of harsh industrial applications.

Meet

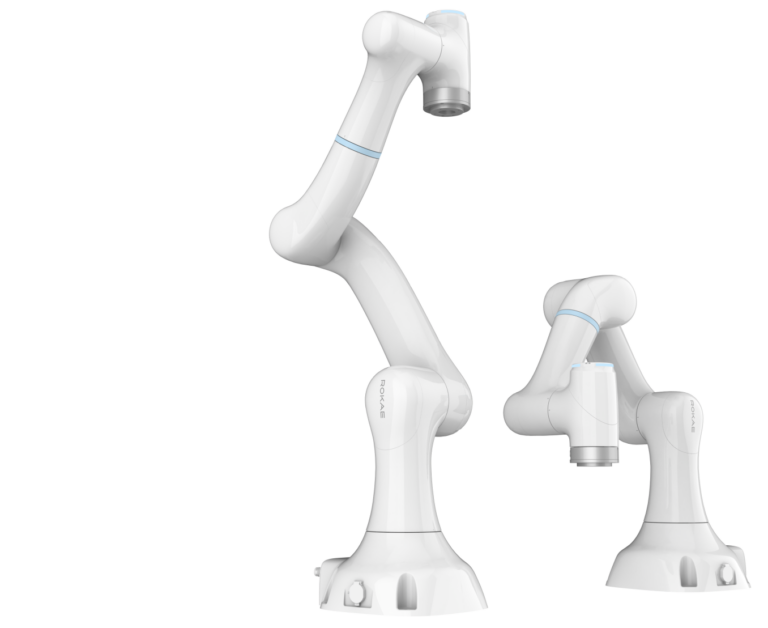

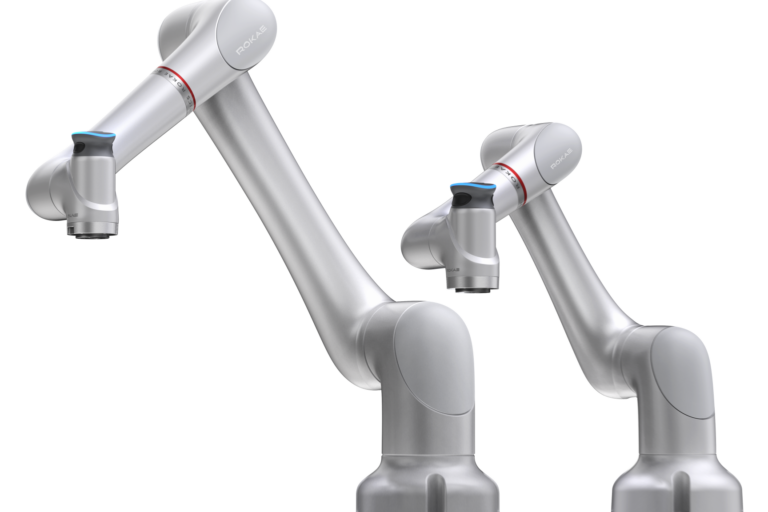

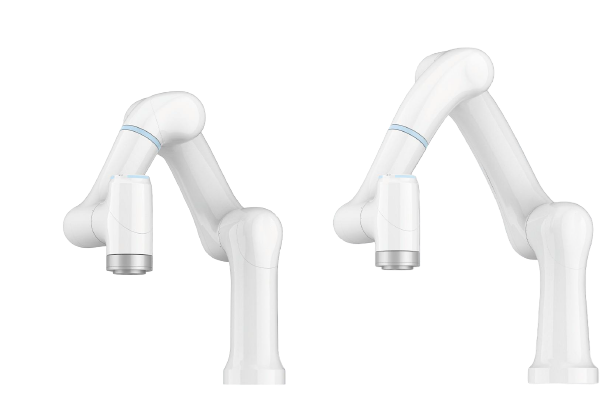

Rokae xMate cobots

SR-C Series

Payload: 3-4kg, Reaches: 705-918mm,IP Level: 54, External controller

series CR-C

Lifting capacity: 7-45kg,Ranges: 988-2047mm,IP Level: 67,External controller

Applications

Metalworking

Palletization depalletization

Other

Machine operation

Welding grinding

Assembly screwing

Loading Unloading

Packaging sealing

Painting blowing off

PCB/ICT support

Rokae ecosystem

Documents

Additional documents

Roka xMate

Need help?

Product information and support:

(+48) 22 299 74 46