Jm-tronik > Robotization of packagingand mixing >

Automatic product mixing

Automated product mixing is a solution for accurately and efficiently combining different types of products in a single bulk package. These systems are an ideal choice for companies that offer promotional kits, samples or differentiated packages tailored to customers’ needs. Using modern technology, it is possible to quickly and accurately sort, mix and package products, significantly increasing productivity, reducing manual labor costs and minimizing the risk of errors. Automating this process is a step toward flexibility and optimization of production operations.

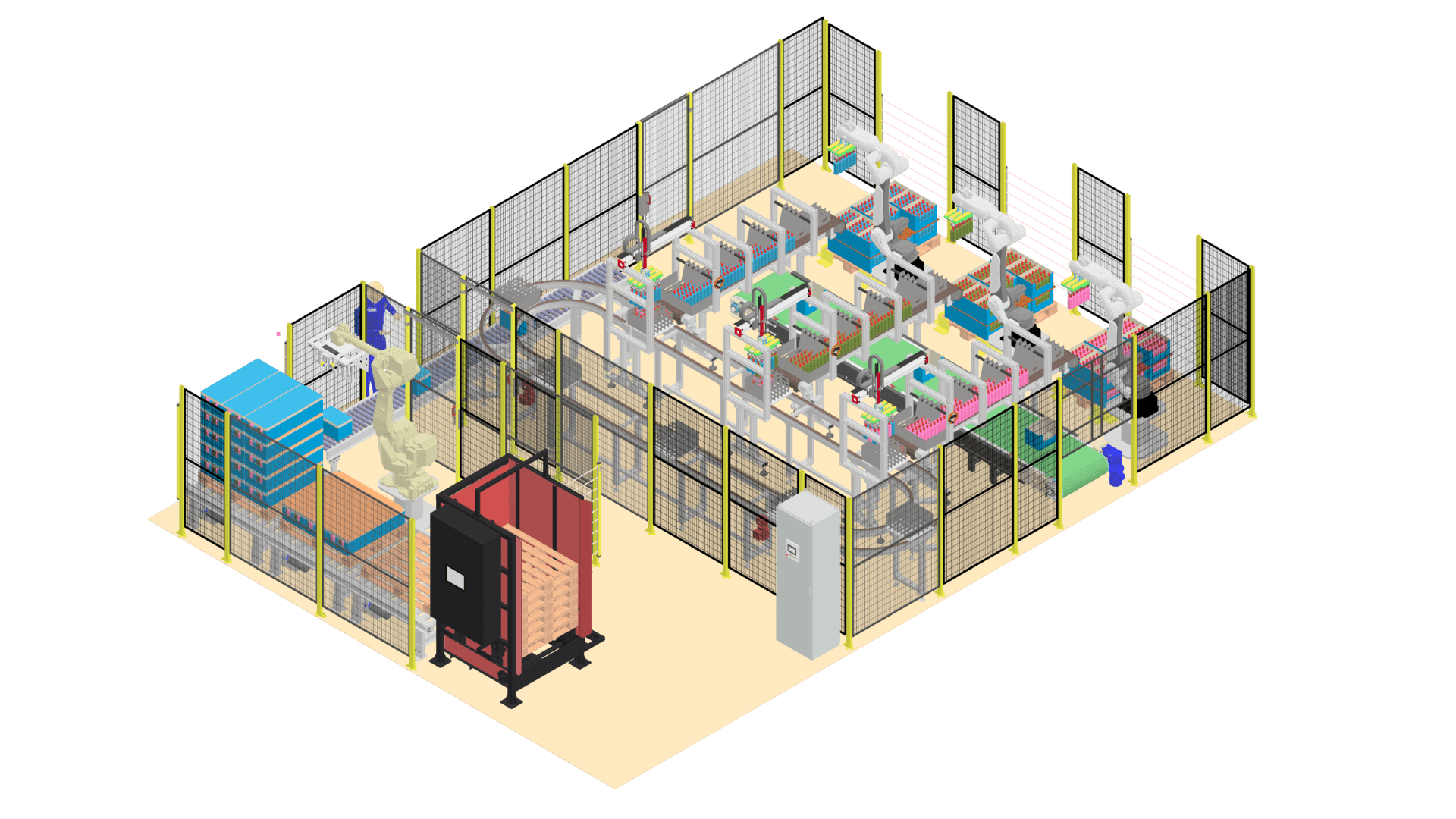

Automatic product mixing - complex packaging and palletizing lines

Automated product mixers are state-of-the-art solutions that combine the sorting, packaging and palletizing process into a single, consistent production line. These systems are designed to precisely and quickly combine different types of products into bundled sets that are perfectly tailored to customers’ requirements. Fully integrated lines allow automation of every step, from product selection and stacking, to packing in cartons or other bulk packaging, to final palletization.

Our comprehensive product mixing lines are flexible and easily adaptable to different formats, weights and packaging configurations. Advanced vision and control systems monitor the quality of each product, ensuring consistency and reliability throughout the process. With this solution, you can optimize the efficiency of your production, increase packaging precision and significantly reduce operating costs, while raising the standard of customer service. This is comprehensive automation that meets the requirements of modern enterprises.

Advantages of automatic product mixing line

Precise sorting and mixing – Vision and control systems guarantee accuracy in product selection, minimizing errors and ensuring consistency of sets.

Versatility – the line handles a variety of packages and products of different sizes and weights to suit individual customer needs.

Increased efficiency – automation of the process speeds up order processing, reducing production time and increasing line efficiency.

Reduced labor costs – the elimination of manual sorting and packaging reduces the need for human labor, reducing operating costs.

Better quality control – monitoring systems detect and eliminate defective or nonconforming products at every stage of the process.

Optimize logistics – integrated packaging and palletizing functions simplify transportation and storage of finished sets.

Scalability and adaptability – lines are easily expanded or adapted to changing production requirements, ensuring a long-term investment.

Get a free audit of production processes in your company!

Find out how much you can gain with our solutions!