Automatic palletizing lines

In an era of rising labor and electricity costs, efficient and flexible solutions are becoming the foundation of competitiveness. We design customized automatic palletizing lines, ensuring process optimization, cost reduction and increased efficiency. With our advanced technologies, your company can operate faster, more precisely and more economically.

Automatic palletizing lines - key to increased productivity and efficiency

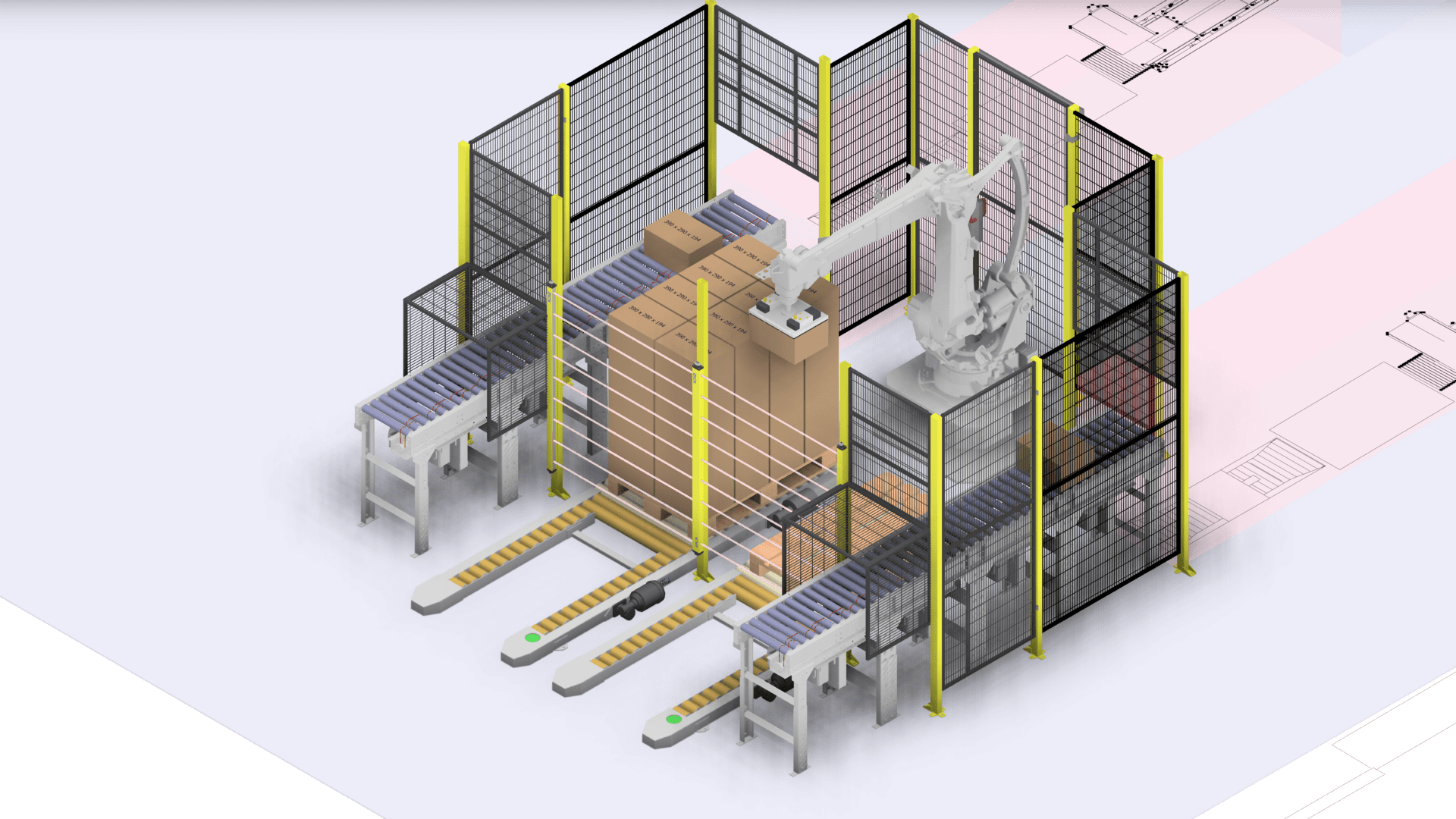

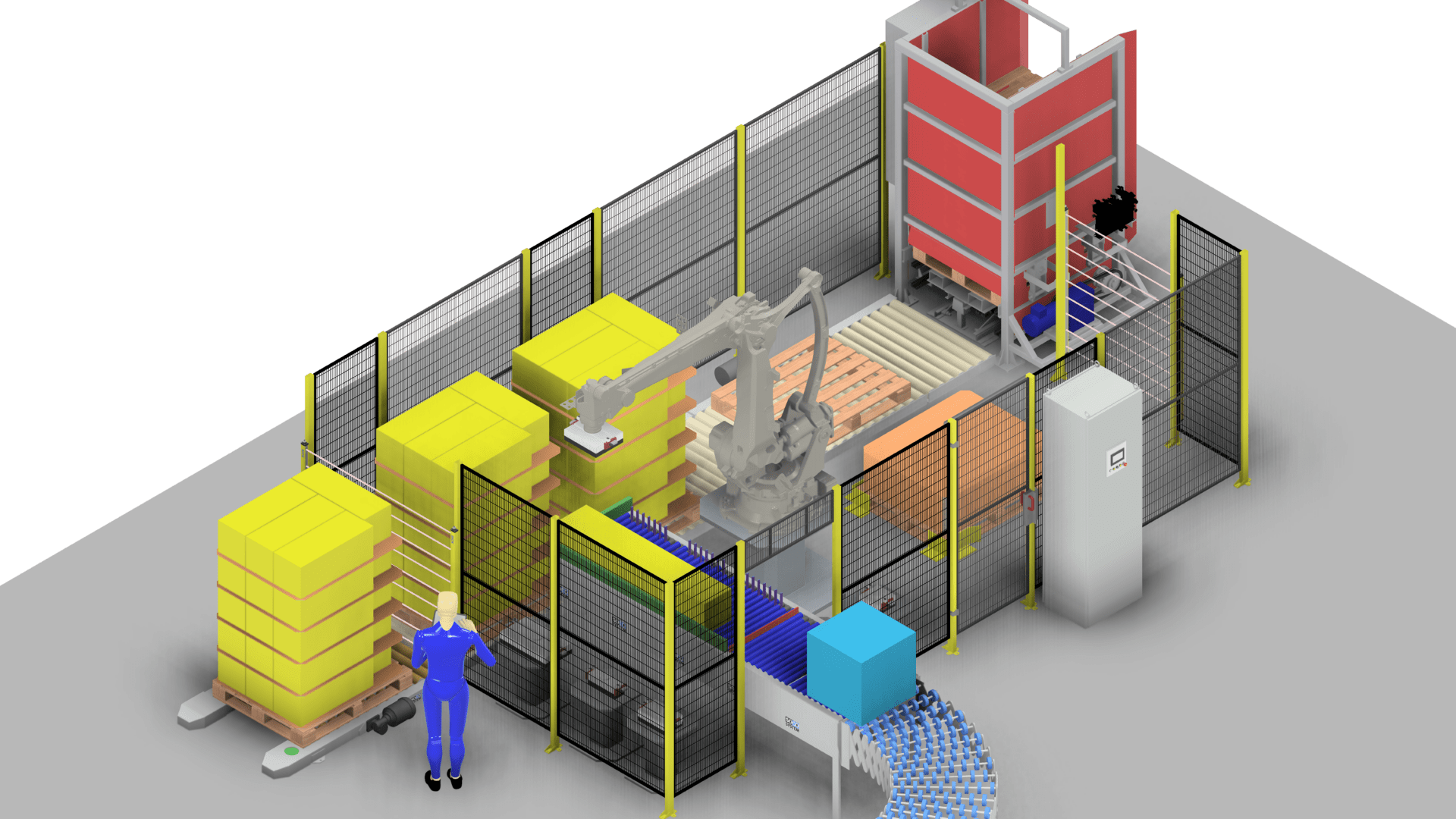

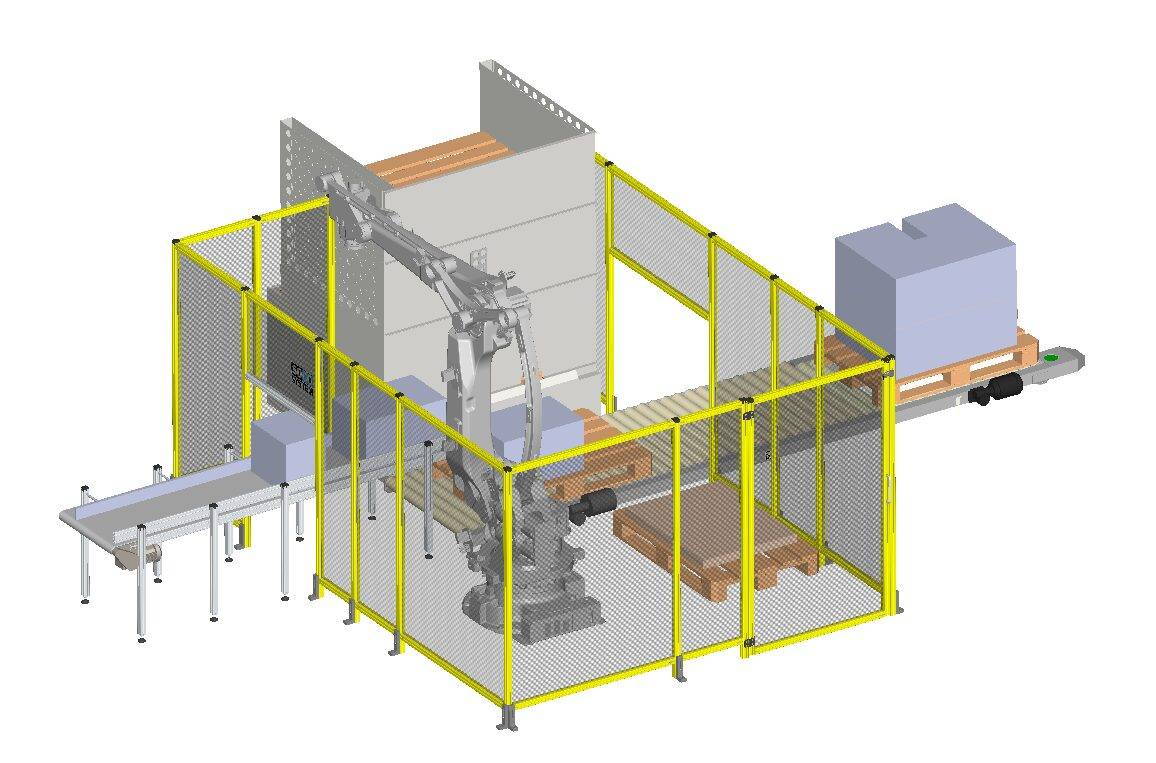

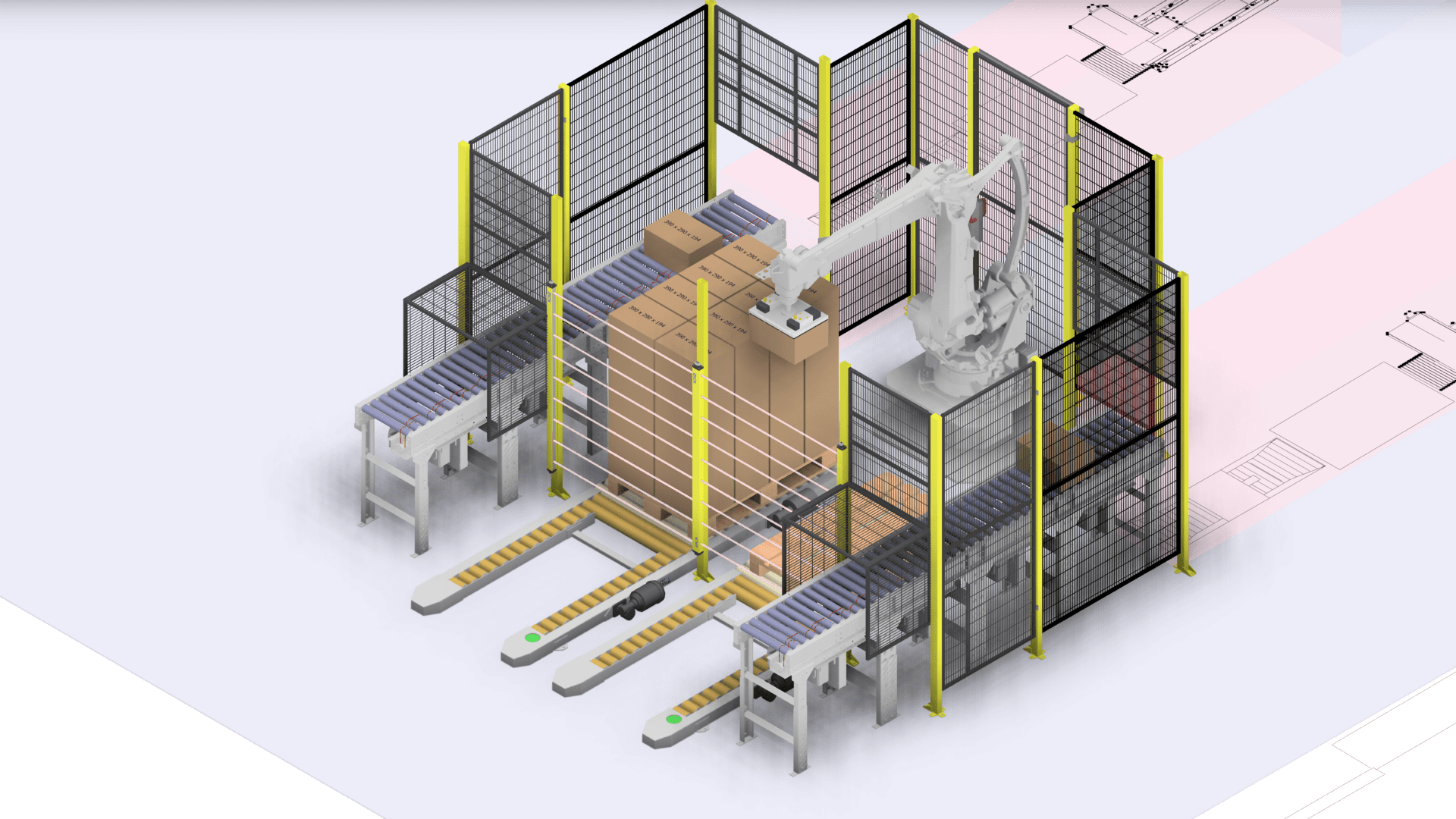

Automated palletizing lines are advanced systems for quickly and precisely stacking products such as cartons, buckets, containers or bags on pallets. Robots make these processes efficient, and their precision and repeatability meet the highest standards.

The systems can be customized both for palletizing single products at the end of the line and several lines in a central system. We support any structure or layout – from single products to entire rows or layers. We offer buffer tables for forming layouts and stabilizing solutions such as dividers or hot-melt glue.

Our lines can be equipped with a flow scale, a label printer with applicator or an integrated pallet wrapper. These are comprehensive solutions that combine flexibility and functionality, tailored to modern logistics processes.

Robotization of palletizing is one of the most frequently automated areas, significantly improving a company’s efficiency and competitiveness.

Advantages of an automatic palletizing line

- Free configuration: support any number of line ends and product types

- Pallet stacking precision: automatic palletizing lines allow precise stacking, resulting in a stable pallet.

- Reliability: the palletizing line works reliably and repetitively without any interruptions, allowing the Employees to be redeployed to other activities.

- Speed and efficiency: The lines can handle large volumes of products in a short period of time, increasing work efficiency.

- Versatility: Adaptable to a variety of product types, from cartons, buckets and bags to unusual shapes.

- Ergonomics and safety: Reducing the need for manual labor reduces the risk of injury and strain on workers.

- Integration with other systems: Can be connected to conveyor belts, scales, label printers or stretch-wrapping systems.

Configuration tailored to your needs

Professional palletizing systems based on large industrial robots offer a wide range of configurations to suit different industry requirements. Each design can take into account product specifics, space constraints and additional requirements for labeling, weighing, quality control and load securing. As a result, efficient and reliable palletizing lines can be designed to meet the most stringent production standards.

Palletizing line to the ideal solution for your business

Application:

- Food industry: stacking cartons of display products, such as candy and beverages.

- Cosmetics and pharmaceuticals: aesthetically palletizing delicate packaging.

- Household chemicals: palletizing cartons of liquids and cleaning products

- Industrial products: stacking cartons in precise configurations.

Advantages for your business:

- Reduction in manual labor costs.

- Increase the precision and repeatability of stacking.

- Improve operational efficiency and lead time.

- Professional presentation of products on pallets, which is especially important in retail.

Various configurations of automatic palletizing line

Boxed and bagged products. Palletizing systems can be adapted to handle products in cardboard boxes, bags or crates. Robots equipped with appropriate grippers (vacuum, fork, jaw or hybrid for display cartons) ensure precise lifting and stacking of loads on the pallet, regardless of shape and material.

Tray products. Palletizing lines designed to stack products on trays often use multi-level grippers or systems with automatic tray feeding as a support layer, providing greater stability during transport.

Large and heavy products. For bulky and high weight products, specialized grippers and high capacity robots are used, which can handle loads weighing up to several hundred kilograms. Such solutions are often used in industrial sectors, such as the construction and chemical industries.

Design for specific requirements

Dimensions and pallet layout

Palletizing lines can handle standard pallets (e.g., Euro) or non-standard formats. Advanced software allows precise definition of product stacking patterns, optimizing space utilization.

Buffer and queuing stations

For large volumes of products, buffer stations are used to allow temporary storage of loads, and queuing systems are used to ensure the smooth flow of products between line stages.

Pallet Warehouses

Automatic pallet warehouses feed empty pallets to the palletizing station, handling different formats and minimizing downtime. Their capacity adapts to production requirements.

Integrated add-on modules:

Labeling: Automatically apply labels according to logistics or legal requirements.

Quality control: Video cameras for ongoing validation of packaging and labels.

Weighing: weighing modules check the weight of products before palletizing, especially important in the food and pharmaceutical industries.

Pallet finish

Interleavers between layers.Lines can be equipped with systems for automatic feeding of cardboard, foil or foam interleavers. These interlayers provide load stability and additional protection for products during transport.

Stretch film wrapping.Automatic stretch filmwrappers that integrate with the palletizing line guarantee robust protection of loads. They can handle different film thicknesses and offer options such as wrapping the top of the pallet or applying printed film.

Get a free audit of production processes in your company!

Find out how much you can gain with our solutions!